Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

- External threads: classified into grades 1A, 2A, and 3A.

- Internal threads: grades 1B, 2B, and 3B. Higher grade numbers mean tighter fits, which is crucial for mechanical assembly compatibility.

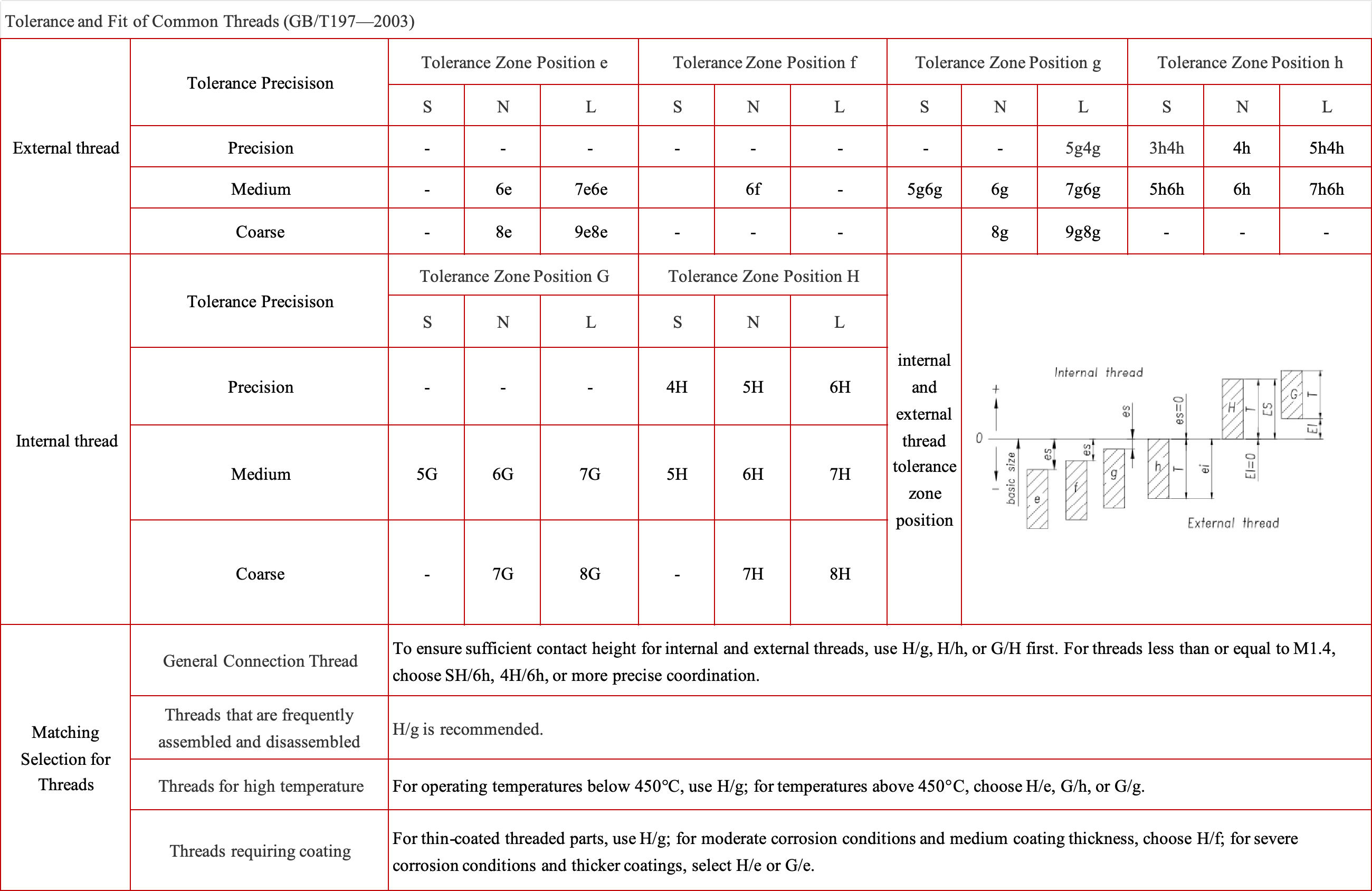

- Grades like 4h, 6h, and 6g define tolerances for external threads for precise fits in various applications.

Go and No-Go Gauges

- Essential tools in precision mechanical manufacturing and quality control. Crucial to inspect if threaded components, including those related to ball screws, conform to standards to prevent assembly issues and ensure mechanical system reliability.

- Produced according to international and national standards like ISO, ANSI, and DIN to ensure thread accuracy and compatibility, which is vital for quality control in ball screw manufacturing.

1) Go Gauge (“T”)

- Verifies minimum tolerance limits of threads. If it can't fully screw into a threaded component (e.g., a ball screw thread), it indicates the thread is smaller than the permitted minimum size, potentially leading to fastening and mechanical failure. It must be calibrated regularly.

2) No-Go Gauge (“Z”)

- Verifies maximum tolerance limits of threads. Should only screw into the component to a specific depth (usually one-third). If it goes deeper, the thread exceeds the standard maximum size, indicating non-compliance.

More efficient than individual precision instrument measurements. Provide a quick way to ensure products, including Ball Screw Components, fall within tolerance ranges, enhancing manufacturing productivity.

For example, with ball screws, if the Go gauge passes smoothly, the thread meets the minimum size requirements. Then the No-Go gauge is used to check maximum size compliance. If it turns more than the specified limit, the thread is non-compliant and should be discarded. The Go gauge is always longer than the No-Go gauge as the Go gauge should fit while the No-Go gauge indicates non - compliance.

The Go gauge ensures parts, such as those of ball screws, fit snugly within the specified tolerance range to confirm compliance. The No-Go gauge is designed to not exceed the upper tolerance limit, marking oversized components as unacceptable.

Go and No-Go gauges are vital for ensuring threaded components adhere to standards. Their efficient use in quality control helps manufacturers maintain high-quality products, avoid costly assembly problems, and produce reliable mechanical systems, enhancing safety and operational efficiency.

September 27, 2024

September 06, 2024

Analysis of the Causes of Ball Screw Clearance Ball screws are precision components widely used in industrial machinery and equipment, playing a vital role in converting rotary motion into linear...

The majority of ball screw pair failures are caused by reduced motion quality, excessive backlash, mechanical creep, and poor lubrication. We will analyze the causes of different failure phenomena of...

The ball screw nut pair is only used to bear the axial load, radial force, bending moment will make the ball screw nut auxiliary surface contact stress and other loads, which may cause permanent...

We can implement effective measures to prevent damage to the guideway. 1. The machine tool guideway should have sufficient and reasonable lubrication conditions. Good lubrication conditions to reduce...

Email to this supplier

September 27, 2024

September 06, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.