Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

We can implement effective measures to prevent damage to the guideway.

1. The machine tool guideway should have sufficient and reasonable lubrication conditions.

Good lubrication conditions to reduce the damage to the guide rail are essential. When the relative movement between the guide surface filled with lubricant, the formation of oil film, the establishment of the liquid friction between the guide surface does not occur direct friction, which occurs between the molecules within the lubricant, which avoids the rail surface of the research loss pull Injury, extend the service life of rails to improve the movement of the rail accuracy.

2. The lathe machine should have reasonable protective measures

To prevent iron filings, abrasive particles, dust, and other impurities into the rail surface, the machine tool rail must have reasonable protection devices. For example, steel plate devices and shields on the rail slide surface end.

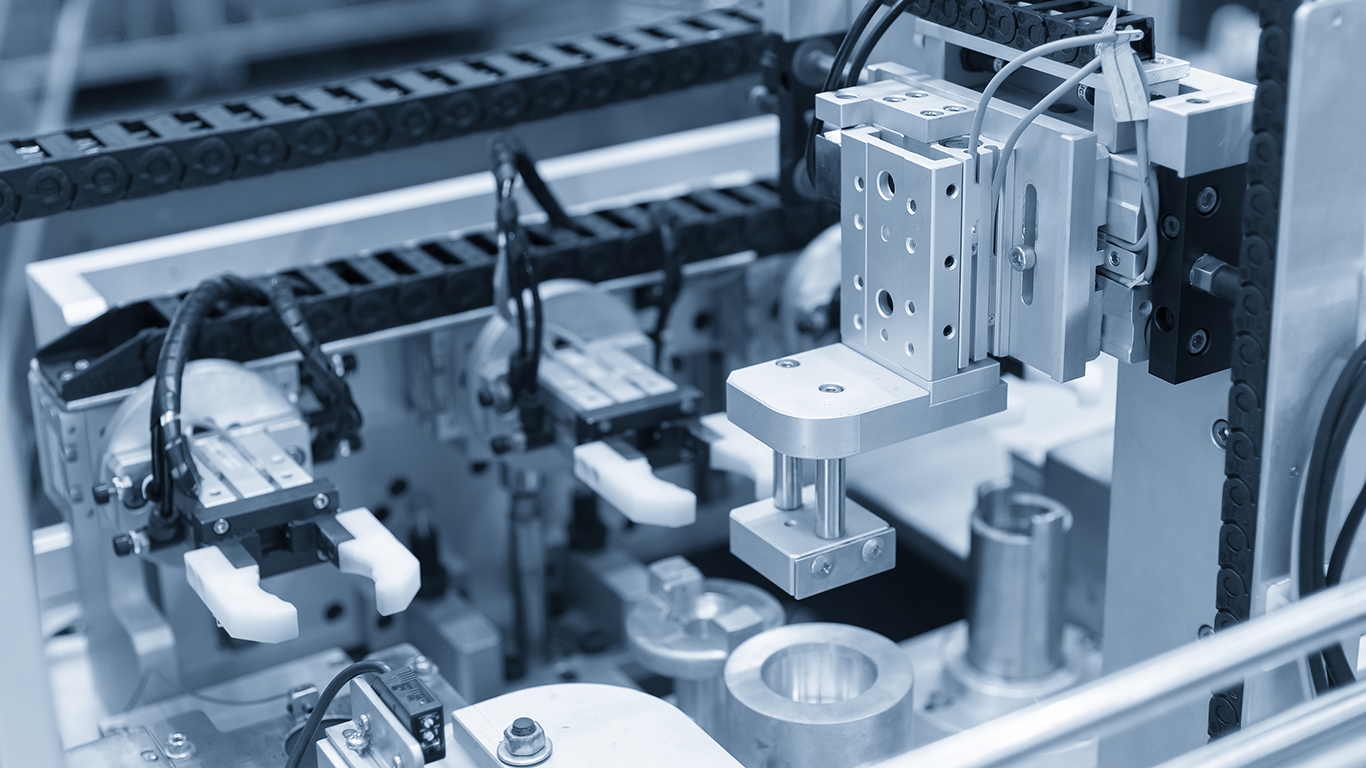

3. Enhance the rigidity of the guideway

Increasing the rigidity of the guide rail is the most straightforward way to reduce or avoid injury.

First, we can do hardening on the surface of the guide surface.

Second, we can also do steel-plated treatment on the rails.

In short, To keep the lathe machine in good condition for a long time, the operator should cooperate closely and do the routine maintenance work of the equipment, keep the lathe machine clean oil regularly, and check it regularly.

September 27, 2024

September 06, 2024

Analysis of the Causes of Ball Screw Clearance Ball screws are precision components widely used in industrial machinery and equipment, playing a vital role in converting rotary motion into linear...

The majority of ball screw pair failures are caused by reduced motion quality, excessive backlash, mechanical creep, and poor lubrication. We will analyze the causes of different failure phenomena of...

The ball screw nut pair is only used to bear the axial load, radial force, bending moment will make the ball screw nut auxiliary surface contact stress and other loads, which may cause permanent...

CNC Machine Parts Ball Screw MIF1602 ——16mm diameter ball screw Quick Details Manufacturing Process: Milled ThreadMaterial: Gcr15 / SS440C(9Cr18) Accuracy grade: C3/C5Length: As...

Email to this supplier

September 27, 2024

September 06, 2024

October 21, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.